Mandrel Lubricant Applicator

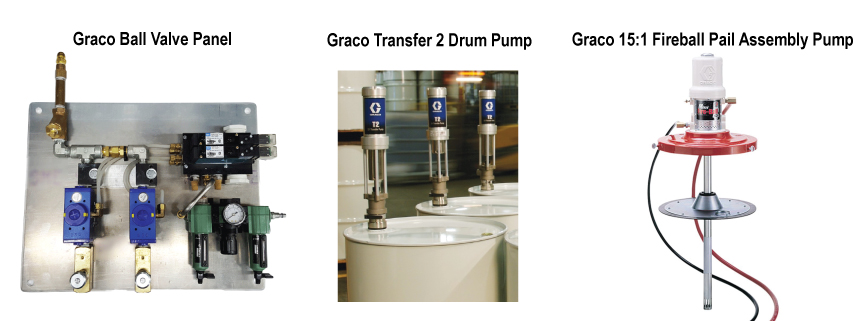

IRMCO GEL® & IRMCO EXTREME® tube bending lubricants are most effectively and efficiently applied using the IRMCO® iV PUMP SYSTEM. This is a system comprised of a lubricant pump integrated with a ball-valve metering assembly that regulates the amount of lubricant pumped through mandrel rods and wiper dies.

Type of Lubricant for Mandrel Application

This applicator can be used with all our IRMCO tube-bending lubricants – including the following series:

IRMCO EXTREME® iTRANSFER & iTRANSPORT System

The IRMCO iTRANSFER & iTRANSPORT system is a two-part chemical containment and transfer system designed to prevent running out of vital process chemistry in production. The 330 gallon IBC of IRMCO iTRANSFER adds convenience through

lowered shipping costs compared to drum quantities and the volume/level sights on both IRMCO iTRANSFER and iTRANSPORT containers allows for visible tracking of remaining IRMCO EXTREME inventory.

IRMCO EXTREME iTRANSFER System includes: an IBC spill containment pallet, GRACO transfer pump and all hose/fittings for pump connection and transfer of product from original tote to iTRANSPORT drum.

IRMCO EXTREME iTRANSPORT System includes: 55-gallon plastic drum with side – sight level/gauge and steel drum dolly.

Our global team strives to surpass our client’s expectations and provide tangible, lasting business and environmental value. Contact us today to learn more about our IRMCO® iV PUMP SYSTEM.

IRMCO EXTREME® iTRANSFER & iTRANSPORT System

The IRMCO iTRANSFER & iTRANSPORT system is a two-part chemical containment and transfer system designed to prevent running out of vital process chemistry in production. The 330 gallon IBC of IRMCO iTRANSFER adds convenience through

lowered shipping costs compared to drum quantities and the volume/level sights on both IRMCO iTRANSFER and iTRANSPORT containers allows for visible tracking of remaining IRMCO EXTREME inventory.

IRMCO EXTREME iTRANSFER System includes: an IBC spill containment pallet, GRACO transfer pump and all hose/fittings for pump connection and transfer of product from original tote to iTRANSPORT drum.

IRMCO EXTREME iTRANSPORT System includes: 55-gallon plastic drum with side – sight level/gauge and steel drum dolly.