The stamping world is always in a state of flux. Material sourcing, logistics, regulations, innovations – there is a culture of constant movement and redesigning of processes for increased efficiencies. In recent years, with materials changes and chemical regulations impacting the market – there has been a greater need for being able to compare the performance of lubricants. Traditionally, this has been conducted in stamping facilities on production dies – interrupting production and increasing the potential for scrap, decreased productivity and limiting the number of products that can be evaluated. IRMCO® knew there had to be a better way for customers to gain the proper data to drive innovation and process improvement and we delivered it; with IRMCO iTool®. Click here to learn more about why to use the IRMCO iTool®.

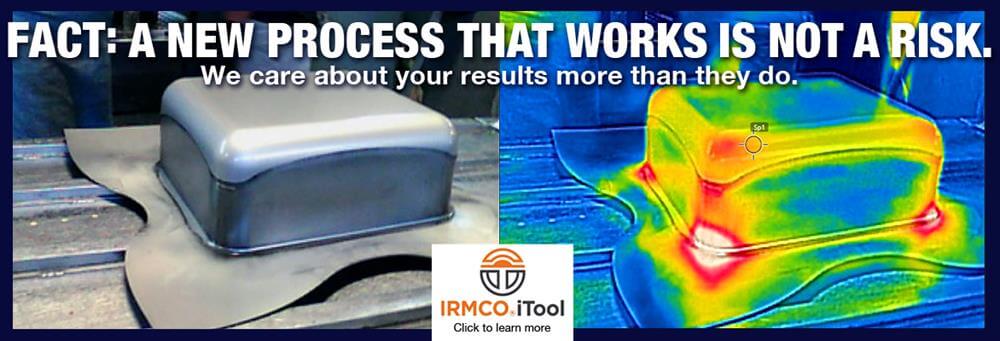

Building upon the proud history of Dr.Taylan Altan’s pioneering research and development at Ohio State University’s Center for Precision Forming – IRMCO created their own tooling and expanded data collection to include measuring thermal differences in tooling and on parts, frictional differences between different lubricants and material thickness of formed parts.

Using blanked materials supplied by the customer, multiple lubricants can be compared on multiple substrates under the same, controlled process – prior to interrupting actual production for field trials. This helps eliminate the “trial and error” guess work by presenting data that has a stronger correlation to production than traditional, laboratory-based frictional testing as the IRMCO iTool® process is actually forming a part.

IRMCO iTool® is a major step in advancing process and efficiency optimization. To learn more about this exciting new process and how it can help better inform your decisions and processes contact IRMCO today.