The newer classes of lubricants have been marketed in numerous ways—but conventionally fall under the description of “water-based evaporative lubricants”.

The newer classes of lubricants have been marketed in numerous ways—but conventionally fall under the description of “water-based evaporative lubricants”.

Most products in this class function similarly to solvent-based vanishing lubricants—but are water-based and contain water-soluble additives that provide similar lubricity and solvency—but do not contain the high levels of V.O.C. of the solvent-based options.

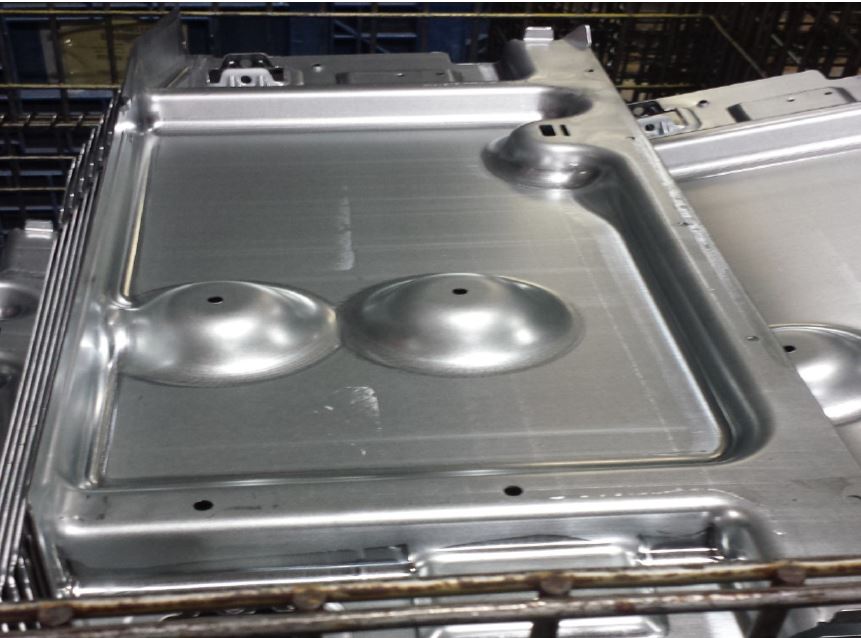

These “evaporative lubricants” are finding utility in some areas of appliance and office furniture markets. Lighter-duty stamping, embossment and perforating applications are most common. The multi-metal utility of these products can vary as some water-soluble additives may not be compatible with some copper containing and/or zinc-coated metals, and aluminum alloys. These products may also “spot” parts if wetting or drying is not complete. These “spots” could appear as stains on part surfaces.

These materials are generally less irritating to skin than solvent-based products and offer improved environmental safety. As with their solvent-based counterparts—products in this class can vary as to level of stamping performance, drying time, dry-down residues and metal compatibility depending upon the level and type of additives in the water-based fluid. As with all “vanishing” &/or “evaporative” stamping fluids—mechanical means can be used to facilitate quicker drying times and control surface residues. Environmental conditions—such as relative humidity—may impact drying time more noticeably than with the solvent-based options.

These types of fluids have experienced some good, marketing-driven success over recent years, but have yet to gain the same level of exposure and general use as conventional vanishing lubricants.