IRMCO specializes in custom, oil-free lubricants for the tube-bending and forming industry. With over 100 years of experience, we understand the standards & quality that are required to work within the industry. Not only were IRMCO products some of the first oil-free stamping fluids- but IRMCO developed the first “gelled” tube-bending lubricants – engineered to “stay put” and be applied in minimal quantity. IRMCO EXTREME® built further upon that success and IRMCO continues to be a leading supplier of innovative, oil-free liquid and gel-type alternatives for all tube-bending markets.

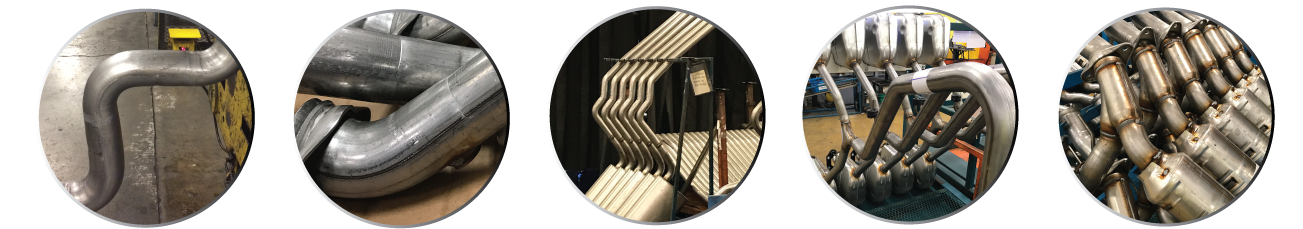

TUBE BENDING SOLUTIONS

During the tube-bending process, IRMCO FLUIDS®, IRMCO GEL® & IRMCO EXTREME® tube-bending lubricants provide internal lubrication of tubes and mandrels during the tube-bending process – while also providing external lubrication for tube outer surfaces & wipers/dies where needed.

Where end-forming, swaging, flaring & other post-bending applications are performed, IRMCO provides clean running, oil-free stamping lubricants for the unique demands of those processes & substrates. Depending upon the post-bending process and tube substrate – IRMCO 080, 090, 146, 323, or 536 series stamping fluids may be recommended to maximize tool life & part quality.

At IRMCO, we work with a complete range of materials to offer customers in the tube-bending industry a large choice in specifications for their oil-free lubrication needs. IRMCO FLUIDS® are safe for mild & stainless-steel materials including CRS, HRS, Aluminized steels, standard stainless-steel alloys, and aluminized stainless steel.

IRMCO GEL® products are available in open-head drums & pails and IRMCO EXTREME® products are commonly available in open-head drums – with one, specialty product available in tote containers. IRMCO FLUIDS® products are available in pail, drum & tote quantities.

LUBRICANTS FOR THE TUBE-BENDING INDUSTRY

- IRMCO FLUIDS® 090-SERIES: this series of fluids is most suitable for smaller, electric, and hybrid benders that utilize “micronized-spray” / “minimal quantity lubrication” (MQL) application through narrow diameter delivery lines through the mandrel. These types of benders would be commonly found in “job shops” or in industries where smaller diameter tubes are processed. The 090-SERIES is suitable for mild steel and standard stainless-steel alloy tubes.

- IRMCO EXTREME® 460-SERIES – this opaque white series of fluids is most suitable for aluminized steel and aluminized stainless-steel tubes ≤ 6” O.D. IRMCO EXTREME® products are easily delivered through the mandrel and offer exceptionally clean bending and weld-through performance.

- IRMCO GEL® 980-SERIES – this series of clear, nearly colorless gel products is most suitable for mild steels and standard stainless-steel alloy tubes ≤ 6” O.D. IRMCO GEL® 980 is easily and optimally applied through the mandrel via the IRMCO I.V. applicator system. IRMCO GEL products offer exceptionally clean bend and weld-through performance.

- IRMCO GEL® 986 – this specialty product is a very viscous, crème-colored product that is most suitable for mild steel and standard stainless steel alloy tubes ≤ 8” O.D. IRMCO GEL® 986 is easily applied through the mandrel or can be applied manually via swabbing. This niche product was developed as an option for larger-diameter tube applications where chlorinated paraffin and pigments are not desired.

TUBE BENDING LUBRICANT BENEFITS

- IRMCO GEL® & EXTREME® products are designed to “stay put” – minimizing/eliminating weeping/dripping and chemical waste.

- All IRMCO GEL®, EXTREME® & FLUID® tube-bending lubricants are easily applied through the mandrel or can be applied manually.

- IRMCO tube-bending lubricants can possibly eliminate intermediate cleaning of tubes between processes.

- Excellent weld-through performance compared to oil-based or pigment-containing competitive lubricants.

- Exceptional cleanliness of operation allows for easier and more complete part/quality inspection.

- Oil-free lubricant composition is easier to clean in aqueous cleaning systems.

At IRMCO, our global team strives to surpass our client’s expectations and provide tangible, lasting business and environmental value. Contact us today to learn more about IRMCO FLUIDS® and our capabilities.

Ask an Expert