Traditionally, the term “vanishing lubricants” implied a product based partly or wholly on volatile solvents or chemicals. Some of the earlier chemicals that enjoyed extensive use were chlorinated solvents which offered excellent punch life and wetting/solvency—but carried serious safety and environmental risks in their use. More recently, base fluids like kerosene, naphtha or mineral spirits are widely used.

Traditionally, the term “vanishing lubricants” implied a product based partly or wholly on volatile solvents or chemicals. Some of the earlier chemicals that enjoyed extensive use were chlorinated solvents which offered excellent punch life and wetting/solvency—but carried serious safety and environmental risks in their use. More recently, base fluids like kerosene, naphtha or mineral spirits are widely used.

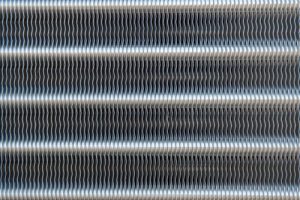

These products offer a modicum of lubricity for light rolling, stamping and embossing of thin gauge metals and for lubricating high-speed, thin-gauge punching applications. Prime examples of these applications include HVAC fin-stamping, stamping decorative brass and copper trim items, light duty shelving brackets and roll-forming of pre-painted aluminum gutters.

Being solvent-based, this class of product contains V.O.C.—which are reportable on SDS and may raise concerns for environmental and/or operator exposure. Newer petroleum-derived and plant-based solvents may technically be categorized as “V.O.C-exempt” – but these “safer solvents” may require lengthier drying times.

For heavier duty stamping applications, conventional vanishing lubricants require additives to improve performance. These additives are typically not volatile and remain on part surfaces after the solvent volatizes. Depending upon the type and amount of these additives in the stamping fluid – the substrate may actually not appear dry at all.

Perceived benefits of using this class of products include comparatively quick drying time to many water and oil-based lubricants and excellent surface wetting/solvency. It is also common for these products to have broad, multi-metal compatibility.