Hardness of diluent water can have a major impact on stamping lubricant performance. Excessively hard water can cause some types of stamping lubricants to form water insoluble compounds that can manifest as sediment in application equipment and in solution reservoirs. This impact of product instability can impair stamping lubricant performance—manifesting as lesser tool life, worsened part finish and decreased corrosion protection if not addressed

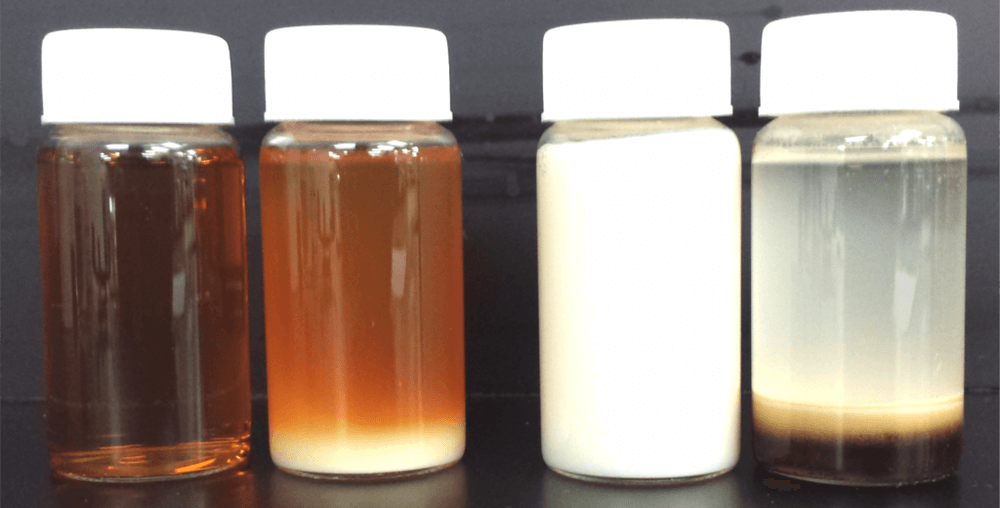

Competitive synthetic stamping fluid @ 4:1 in DI (L) and 4:1 In hard water (2nd L). Competitive emulsifiable oil @ 4:1 in DI (2nd R) and 4:1 in hard water .

Some classes of stamping lubricants may only suffer a depletion of one or two ingredients through the hard water compounds that form. Other classes of stamping fluids may outright split out of solution and form either surface layers/cremes or thick sediments that clog filters and equipment.

As illustrated, the same two lubricants that are very stable in DI water show dramatic instability and sedimentation in hard water. For these reasons, IRMCO recommends customers understand their water quality and helps to identify possible ways to address any areas of concern.