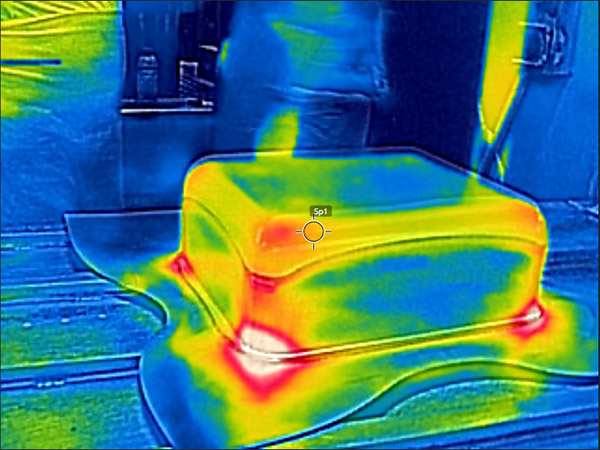

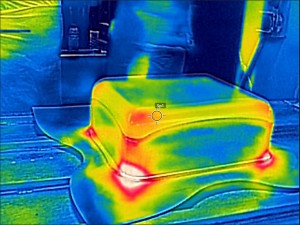

Thermographic analysis has been used for years in defense systems, HVAC troubleshooting applications and failure analysis in areas of manufacturing. The infrared images can help isolate localized areas of high temperature and/or friction and aid in better die and process design and improvement. Used in conjunction with other metrics from process monitoring, a stamping process can be optimized for efficiency and consistency.

IRMCO® utilizes thermography not only in monitoring/analyzing customer processes, but also in the development and screening of lubricants in our iTOOL® process. Based on the time-tested “cup drawing process”, IRMCO’s iTOOL die can evaluate numerous factors in lubricant performance on any supplied metal substrate. In addition to cup & flange dimensions, surface appearance and measured peak load, IRMCO can measure and record thermal images of trial parts to compare a lubricant to one or more other lubricants in the same test matrix. This enables customers to evaluate lubricants more comprehensively prior to interrupting their own production – minimizing downtime and potential scrap costs.

Thermography is just one of many weapons IRMCO can provide you to fight friction and excessive die wear. Clearly pointing out areas of higher friction and metal stress – this imagery can aid in better die design, better directed and optimized lubricant application and greater efficiencies through your production cycle.

IRMCO invested in the iTOOL testing program because we believe there is a better way to screen lubricants and stamp parts.